Manufacturing is the process of converting raw materials into finished products. In manufacturing, there are several different methods of producing a product. A common method is called Lean Manufacturing, which aims to create a more efficient production process. If you have the right skills, you can pursue a career in manufacturing.

Manufacturing is a simple process

Manufacturing is an essential aspect of life, and has been since time immemorial. A manufacturer needs to be able to churn out goods at a reasonable price, and to a quality level that will keep customers coming back for more. This is best accomplished by leveraging the right mix of sales, marketing, production and stock management tools.

The modern manufacturing industry is more diverse than ever. For instance, there are companies producing cars, toys, and apparel to name a few. The industry has also seen a surge in the number of startups and high-profile IPOs. To help navigate the maze that is the industrial revolution, a number of industry bodies have been created to inform and educate financial analysts.

While some industries may require a complete overhaul of their operations, many companies can be quickly and efficiently upgraded to meet customer demands.

Manufacturing can be divided into different production methods

Manufacturing can be defined as the process of assembling or processing raw materials and components into finished products. It is an important industry that has existed for centuries.

There are many different manufacturing processes. Each one has its own characteristics, skills and requirements. The type of manufacturing you choose can depend on the nature of the product.

For instance, a T-shirt manufacturer might opt to do make to order manufacturing. This is a system where the company creates custom-made products based on the design and size of the customer’s orders.

Another example is batch process manufacturing. Batch production is a large-scale process that produces a batch of finished goods at a given rate. Often, batch manufacturing is more efficient than other methods of producing the same or similar items over and over.

Quality control is a big factor in successful manufacturing

Quality control is the process of evaluating and testing products to determine whether they meet the company’s specifications. It is an important part of ensuring that customers are getting the quality of products that they paid for.

There are many ways to implement quality control in your business. The methods you use will depend on the product you are producing and your industry.

A good quality control system will also ensure that your employees are performing their tasks properly. This helps avoid accidents when your customers are using your product.

Quality control involves the review of all aspects of a project. You can monitor significant variations in the manufacturing process, and then make adjustments. In the automobile industry, for example, quality control focuses on parts meeting tolerances.

Lean manufacturing helps to create a more efficient production process

Lean manufacturing is a production method that reduces waste and creates a more efficient process. Whether you are a small business or a large corporation, lean can help you create a more efficient workflow.

The main goal of lean is to eliminate processes that are not adding value to the end product. This is done by analyzing the process and identifying areas that need improvement.

To do this, a company must create a system for processing steps. These include transitions between processing steps and the use of standardized work instructions.

Streamlining these procedures can help minimize lead time, reduce production costs, and increase employee satisfaction. In addition, improved productivity can improve sustainability and increase profits.

When implementing a continuous improvement strategy, a manufacturer must consider the input from all employees. They also need to monitor and control the procedures.

Manufacturing jobs can cover a wide range of skills

Manufacturing jobs require a variety of skills, and a wide range of experience is required to do well. In addition, some occupations may require certification from a professional association.

Many manufacturing jobs require a good eye for detail. You’ll need to be skilled in quality control, precision, and the ability to work without supervision. A good attention to detail will protect you and your colleagues, and help you get the job done efficiently.

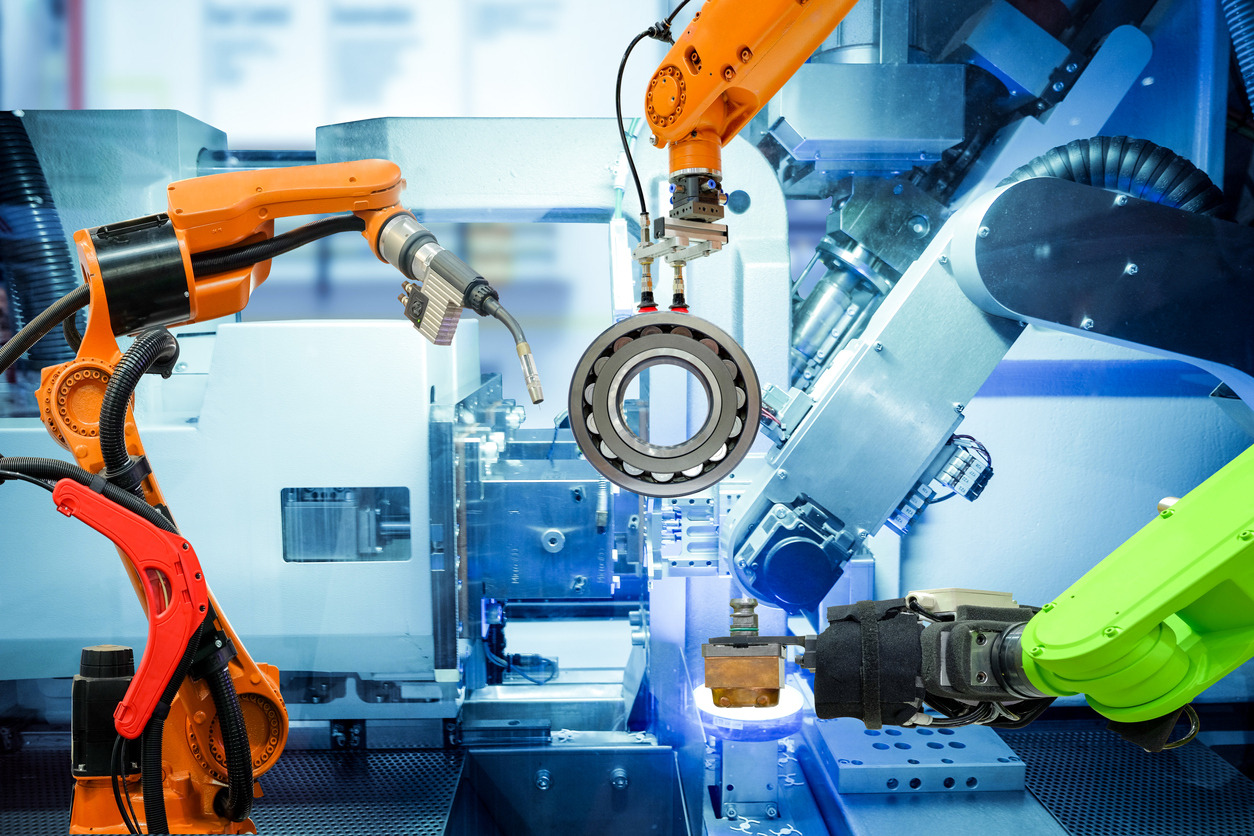

Manufacturers are always looking for ways to improve their operations. They use computers, robotics, and other advanced technology, but they need employees with a variety of skills. The right skills can help you get the job, and can lead to higher pay.

Jobs in manufacturing can be challenging and rewarding. While you might have to start out with a minimal amount of experience, there are many opportunities available.